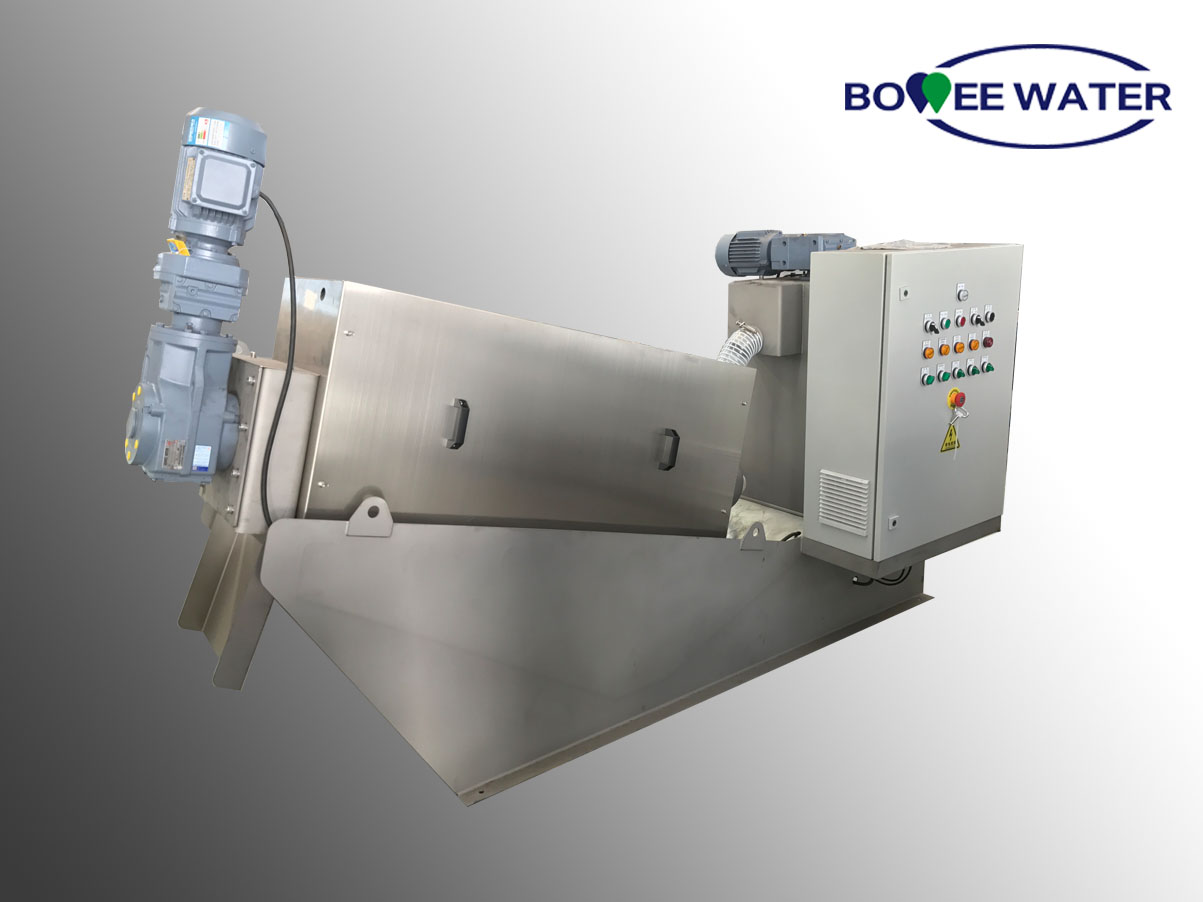

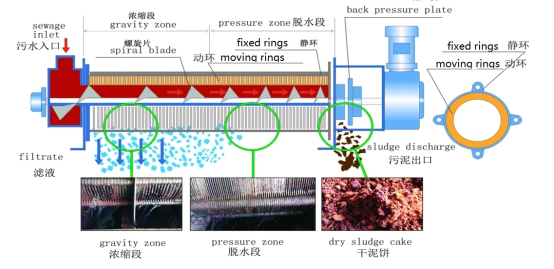

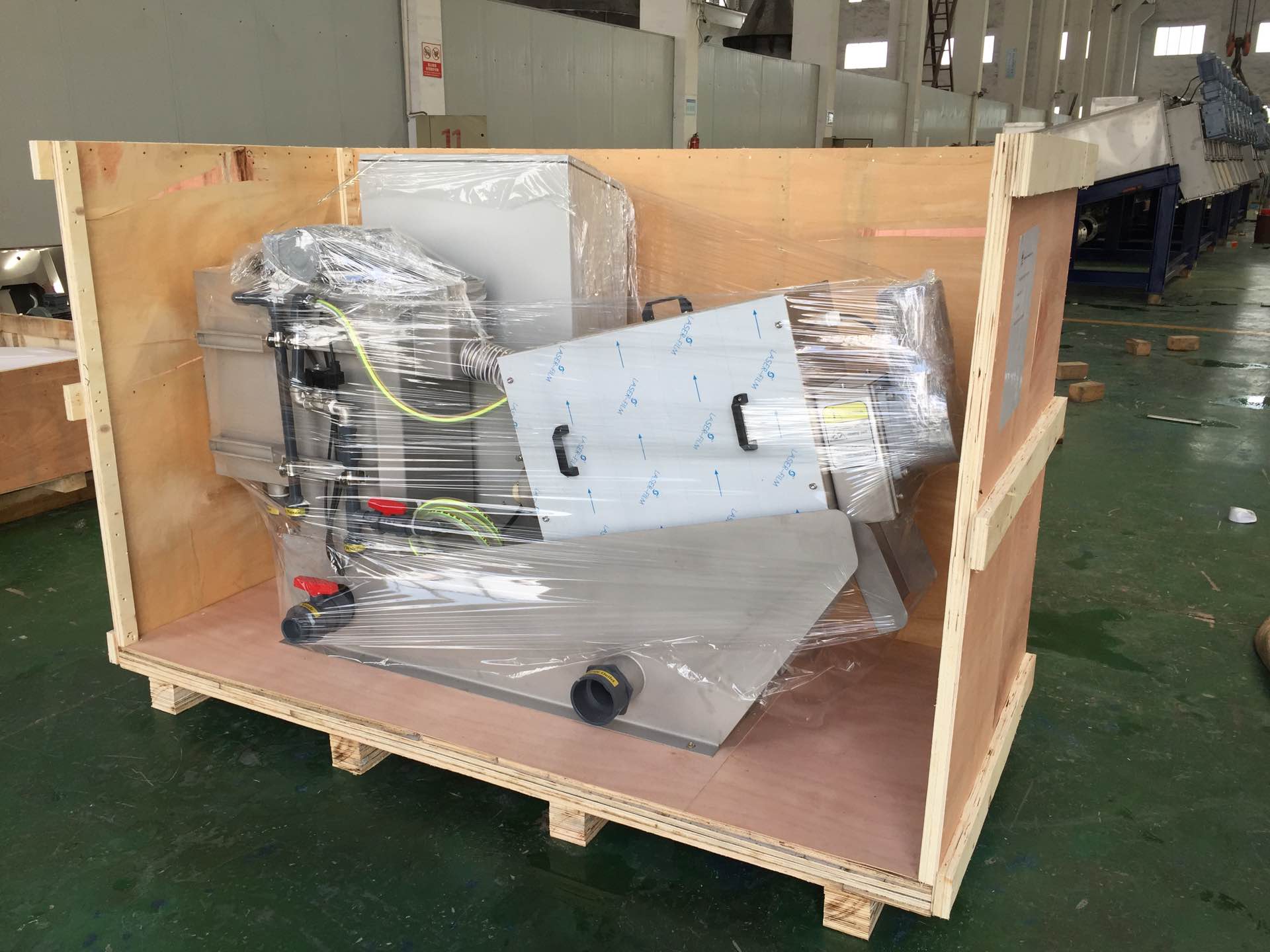

Dewatering screw press is used for efficient thickening and dewatering of sludge waters. Sludge waters are water, containing certain amount of suspended solids, these can be product of waste water treatment, food proccessing industry, chemical industry and other branches of human activity.

Specifcations:

Dimension: Customized

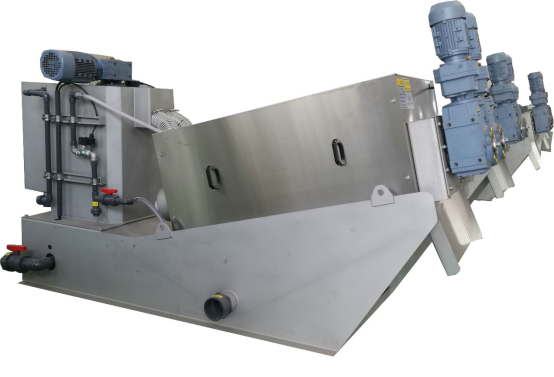

Capacity:6-600kg DS/h

Material:SS304 or SS316

Motor:First-class motor, Nord or SEW is optional